The Sales & Operations Planning process: aligning sales and production

“Experience shows that if you plan your desired project well in advance, you can act quickly when the time comes to execute it.” (Cardinal Richelieu)

Today’s increasingly competitive and unstable markets demand that companies pay close attention to managing their raw material supply chain and the underlying sales and operations planning process. In fact, increasingly shorter product life cycles, unstable demand heavily influenced by external factors, and international supply chains make sales and production planning even more challenging than it already is.

Let’s start by establishing a common understanding of what we mean by S&OP: at a high level, the S&OP process involves aligning the entire company on which products to produce, identifying the right production sites, and selecting the appropriate markets.

More specifically, this process plays a crucial role in utilizing available resources, such as raw materials, and in an organization’s production capacity. For instance, if certain products or semi-finished goods are not in the right warehouse or are not available for production at a specific time, the organization could face a stock shortage. Conversely, if they are available, the organization might end up with excess inventory and a lack of sales.

The S&OP process must ensure the right product is produced in the right quantity and at the right location, using factors such as cost planning, demand forecasting, and risk management.

In the day-to-day management of any company’s business, constraints and/or a lack of resources significantly influence an organization’s decision on how to allocate these resources throughout its supply and production chain. This situation can lead to a lack of trust between the sales and production departments, resulting in unmet expectations, unproductive behavior, and increased stress. These obstacles hinder the basic objectives of the S&OP process, which aims to optimize resource utilization to deliver superior customer service compared to the competition. Lacking products for key markets while having excess inventory of other products are signs of a dysfunctional S&OP process.

So how can we create an S&OP that is functional? Following the Lean Lifestyle approach, the evolution of Lean Thinking simultaneously achieves more results and more well-being. To improve performance in a sustainable way it is necessary to act both on the technical aspects – and therefore on the processes and tools – and on the social aspects – and therefore on people’s habits and behaviors.

Technical excellence

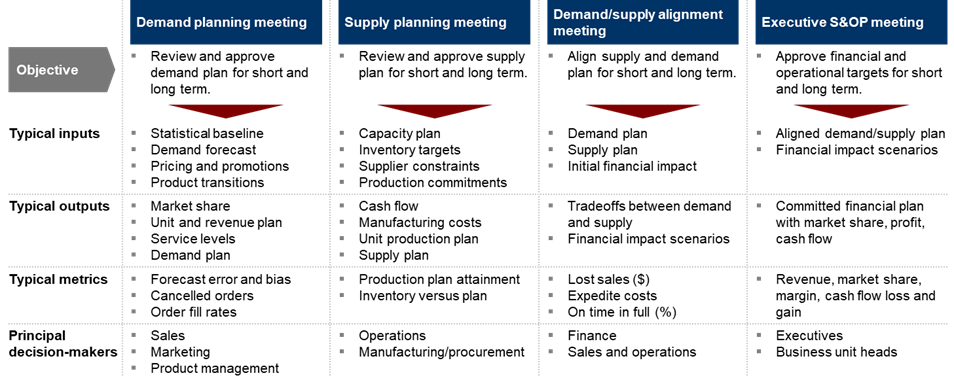

A necessary but not sufficient condition for building an effective and efficient S&OP process is to draw in detail, with respect to the specific company business model, the different phases that make up this process, specifying which opportunities for meetings between the different company functions are foreseen, which are the inputs, outputs and expected metrics.

Here we see an example of a typical S & OP process, consisting of frequent meetings between different stakeholders which has its objective of making crucial decisions regarding the current management of the business on a regular basis.

Balancing supply and demand, costs and service levels are an ongoing problem, requiring regular meetings between different business functions to address myriad small decisions and reviews every day.

Once the drawn process has been drawn and run in, the following aspects must be considered:

1. Reliable information

In implementing the new S & OP process, many companies turn their attention to many details, useful on a tactical level, but not important on a strategic level to make the whole process work (think, for example, of the incessant research regarding technological tools that are believed to make the process work better)

Unfortunately, many companies do not realize on the other hand, the importance of input for the whole process, that is, the necessary information and data that inform the decision-making process.

Having reliable and transparent information is vital to evading problems arising from the imbalance between supply and demand and supports decision-making at strategic, operational and transactional levels within the company. It is therefore imperative to harmonize supply and demand data before making any decisions regarding production and stock allocation.

For example, the unfulfilled order book must be compared simultaneously with the existing stock situation and planned production, to provide a real view of stock positions and item availability.

2. Segmentation

Demand forecasting plays a critical role in efficiently managing the balance between the required market demand and the supply that the company can produce. Segmentation of products, channels and customers, based on certain key factors, such as volume, demand predictability, product life cycle stages and supply chain impact, enables more effective and efficient demand forecasting and enables, for example, the ability to predict in advance the possibility of depleted or surplus stocks, thereby harnessing the energies of the company to react in time and appropriately.

When properly implemented, segmentation can bring several benefits:

- It helps to decide the degree of flexibility of production planning.

- It helps develop procedures and instructions to manage expected tradeoffs to align supply and demand, minimizing the possibility of exacerbating problems and accelerating decision making.

- It helps to define supply chain parameters according to the magnitude of demand that production, and more generally the company system, can absorb without breaking down –for example, an overshoot of the level of demand relative to the installed capacity of a company may indicate a new market trend that may require the restoration of supply chain parameters, such as increasing production capacity or adjusting logistics.

Technical excellence

A necessary but not sufficient condition for building an effective and efficient S&OP process is to draw in detail, with respect to the specific company business model, the different phases that make up this process, specifying which opportunities for meetings between the different company functions are foreseen, which are the inputs, outputs and expected metrics.

Here we see an example of a typical S & OP process, consisting of frequent meetings between different stakeholders which has its objective of making crucial decisions regarding the current management of the business on a regular basis.

Balancing supply and demand, costs and service levels are an ongoing problem, requiring regular meetings between different business functions to address myriad small decisions and reviews every day.

Once the drawn process has been drawn and run in, the following aspects must be considered:

1. Reliable information

In implementing the new S & OP process, many companies turn their attention to many details, useful on a tactical level, but not important on a strategic level to make the whole process work (think, for example, of the incessant research regarding technological tools that are believed to make the process work better)

Unfortunately, many companies do not realize on the other hand, the importance of input for the whole process, that is, the necessary information and data that inform the decision-making process.

Having reliable and transparent information is vital to evading problems arising from the imbalance between supply and demand and supports decision-making at strategic, operational and transactional levels within the company. It is therefore imperative to harmonize supply and demand data before making any decisions regarding production and stock allocation.

For example, the unfulfilled order book must be compared simultaneously with the existing stock situation and planned production, to provide a real view of stock positions and item availability.

2. Segmentation

Demand forecasting plays a critical role in efficiently managing the balance between the required market demand and the supply that the company can produce. Segmentation of products, channels and customers, based on certain key factors, such as volume, demand predictability, product life cycle stages and supply chain impact, enables more effective and efficient demand forecasting and enables, for example, the ability to predict in advance the possibility of depleted or surplus stocks, thereby harnessing the energies of the company to react in time and appropriately.

When properly implemented, segmentation can bring several benefits:

- It helps to decide the degree of flexibility of production planning.

- It helps develop procedures and instructions to manage expected tradeoffs to align supply and demand, minimizing the possibility of exacerbating problems and accelerating decision making.

- It helps to define supply chain parameters according to the magnitude of demand that production, and more generally the company system, can absorb without breaking down –for example, an overshoot of the level of demand relative to the installed capacity of a company may indicate a new market trend that may require the restoration of supply chain parameters, such as increasing production capacity or adjusting logistics.

Social excellence

Awareness of the importance of the S & OP process among Corporate Leadership is instrumental to the execution of correct and functional behaviors to the process. Top management must be actively involved in decision-making at the strategic level in certain priority areas, such as pricing and expanding productive capacity, where these critical decisions can develop a competitive advantage over the competition.

A further responsibility of Corporate Leadership is to ensure mutual respect and support between company functions.

Taking a reality bath, we can say that the objectives of sales and operations functions often diverge: operations wish to reduce inventory levels, maximize resource consumption, and minimize overall costs by refining forecast accuracy and demand management, while the sales function is expected to meet sales and margin targets, and in general it is not prepared to engage in forecasting as it wants more flexibility and excess stock so as not to lose a single sale.

This inter-functional mismatch can result, for example, in very overestimated sales forecasts or even non-attendance at S & OP meetings by the required participants.

Strong Leadership must take concrete measures to correct these problems, for example by introducing incentives and metrics that favor behaviors functional to the process by inter-functional nature of S&OP, sharing with the different functions shared sales and operational objectives that push for the improvement of performance throughout the organization.

Equipping yourself with a solid and deep Sales & Operations Planning process within the company is no longer an option but has become an imperative for any company.

Reliable data and information, segmentation of products, channels and customers and present and incessant engagement of business leadership are the ingredients that allow the process to function and continuously improve, allowing companies to build a fundamental piece to be visionary and pragmatic at the same time.

Articolo a cura di:

Riccardo Siciliani

former Manager Lenovys

He is a Manager in the Delivery Unit Strategy & Innovation at Lenovys, and manages projects related to the definition and implementation of corporate strategies, the innovation systems and application of Lean Product and Process Development principles with clients operating in the manufacturing, food & beverage and financial services sectors.

Read more

Prossimi eventi